Pickled Sheets

The pickling line is a crucial process in steel metallurgy, primarily used to remove surface scale from steel sheets in preparation for subsequent processing (such as rolling).

Classification:

Pickled Coil

Key words:

Pickled Sheets

Graphic Details

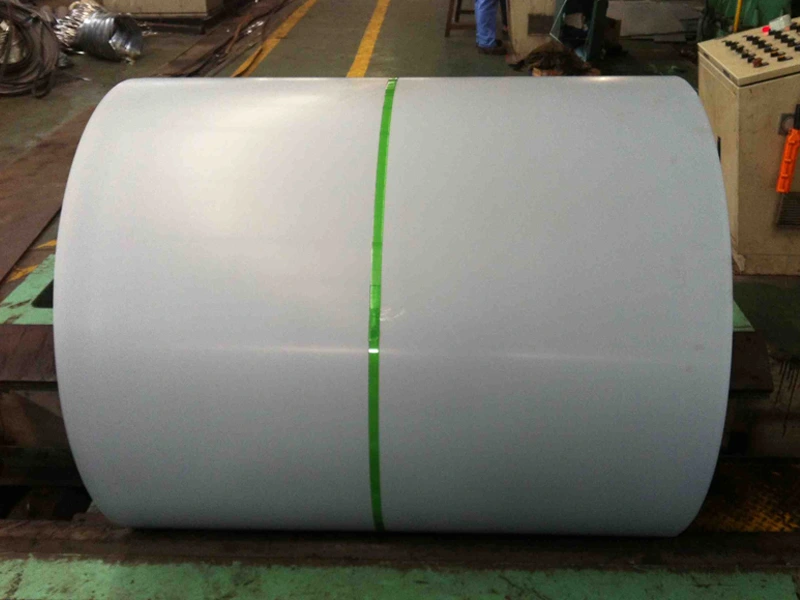

Pickled Sheets

As a kind of pickling-treated steel sheets, they are primarily used in the manufacturing of high-end kitchenware, construction materials, automotive components, and other fields. To produce them, steel sheets are treated in the pickling equipment and pickling solution to remove surface scale, iron oxide, and other impurities to meet the processing and surface quality requirements.

In terms of the production process, we firstly select high-quality raw materials for cutting and cold rolling treatment to produce sheets of specific dimensions. Then, these sheets are immersed in pickling tanks to remove surface scale and impurities. Following this, rinsing, degreasing, drying, and other subsequent processes are done, ultimately producing finished pickled sheets featured with high hardness, great strength, excellent tensile properties, and high corrosion resistance.

The pickling line is a crucial process in steel metallurgy, primarily used to remove surface scale from steel sheets in preparation for subsequent processing (such as rolling).

Push-pull Shallow Groove Turbulent Pickling Line:

Characteristics: It is a discontinuous pickling unit and a good solution for medium and small-sized cold rolling mills. Its advantages include low investment, a simple structure, strong adaptability, and easy operation and maintenance.

Structure: It mainly comprises an entry section, a chemical process section, and an exit section. The strip steel is driven by the push-pull of the pinch rolls and squeeze rolls during the threading process. After entering the coiler pinch, the strip steel is pulled by the tension of the coiler. In order to meet the speed regulation requirements during strip threading and operation and the constant tension requirements for strip steel unwinding and coiling, the main equipment of the unit is driven by a DC motor or an AC variable frequency motor. The interlocking of the mechanical equipment, the action and interlocking of the hydraulic drive and the pneumatic equipment are under the real-time tracking and automatic control of a programmable logic controller (PLC), supported by a computer and terminal display (manual operation is allowed when necessary). The interlocking of all AC motors in the chemical process section, and the PID regulation of all medium temperatures, flow rates, and pressure regulating valves are achieved also by a PLC, supported by computer-based supervisory control and terminal display.

Others

Contact an expert to solve the problem now!

CONTACT INFORMATION

location

Address

Dianzi Industrial Park, Boxing County, Binzhou City, Shandong Province, China

国际站建设:中企动力 淄博 外贸Google推广